It is a crucial step to keep the excavator hydraulic pump clean to maintain optimal performance and lifespan. Regular cleaning helps prevent extra expenses such as repair or replacement costs, while also ensuring the reliable operation of the hydraulic system. In this article, we’ll provide you with effective cleaning tips.

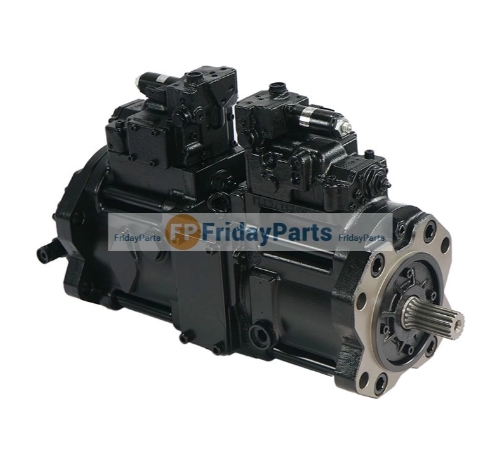

What is an excavator hydraulic pump?

The hydraulic pump is the core component responsible for powering hydraulic operations in excavators, enabling functions like digging, loading, and lifting. Thus, maintaining the pump’s proper functioning is essential for the excavator’s performance and operations.

How to clean the excavator hydraulic pump?

Step 1: Preparation

Turn off the excavator’s engine and ensure the hydraulic system is depressurized. And refer to the excavator’s manual to locate the hydraulic pump and understand relevant operational details.

Step 2: Surface dirt removal

Use a clean cloth or brush to remove dust, oil stains, and debris from the hydraulic pump’s surface.

Importantly, ensure that no external dirt enters the pump’s internals during the cleaning process.

Step 3: Disassembly of the hydraulic pump

Refer to the excavator’s manual or seek guidance from hydraulic pump suppliers or shops to disassemble the pump. Because it may involve disconnecting piping, bolts, and support structures.

Step 4: Internal cleaning

Use an appropriate cleaning agent, such as mineral oil or specialized cleaners, to wash the internal components of the hydraulic pump. You can apply the cleaning agent evenly using a spray gun or brush, avoiding direct spraying on critical components like seals and bearings.

Step 5: Flushing the hydraulic pump

Rinse the hydraulic pump’s internals thoroughly with clean water or compressed air to remove traces of cleaning agents and dirt. Please ensure thorough cleaning to prevent adverse effects on the hydraulic system.

Step 6: Drying and inspection

Place the hydraulic pump in a well-ventilated area to air dry naturally. Avoid using high temperatures or strong winds for accelerated drying.

Before reassembly, carefully inspect all pump components for damage, wear, or looseness.

Step 7: Reinstallation of the hydraulic pump

Follow the excavator’s manual instructions to correctly reassemble the hydraulic pump. Ensure proper installation of piping and support structures, tightening bolts securely.

FAQs

What signs indicate the need for replacement during cleaning?

If you find signs such as oil leaks, unusual noises, overheating, or abnormal vibrations during cleaning may indicate potential issues requiring replacement. Further inspection is recommended to determine the cause.

How much does a new excavator hydraulic pump cost?

The price of a new hydraulic pump for excavators ranges from hundreds to tens of thousands of dollars, depending on factors such as brand, model, capacity, seller location, etc. Generally, higher hydraulic power requirements in excavators typically entail higher pump costs. Check the price of a new excavator hydraulic pump.

How much does it cost to replace a hydraulic pump for an excavator?

Generally, professional replacement costs are higher than DIY, because of the labor costs and geographic factors. While professional replacement ensures safety and reliability, it can be a significant expense.

Where to buy a high-performance hydraulic pump?

FridayParts works to provide compatible replacement parts for various excavator brands and models at competitive prices. With a focus on quality and excellent customer service, we offer hydraulic pumps that are easy to install and durable compared to other options.

To learn more about great blogs, please view blog.fridayparts.com.

Leave A Comment