Hydraulic pumps are vital components that control the direction and speed of machinery such as excavators, agricultural equipment, and lawnmowers. They operate quietly, with low maintenance costs, making them highly sought-after investments in the construction and agricultural sectors. However, if hydraulic systems are overloaded, it can lead to incorrect pressure values, potentially damaging the pump and other components. That’s why we share the adjustment output pressure of hydraulic pumps with you. Take a look at them now, it is easy to get.

What is a hydraulic pump?

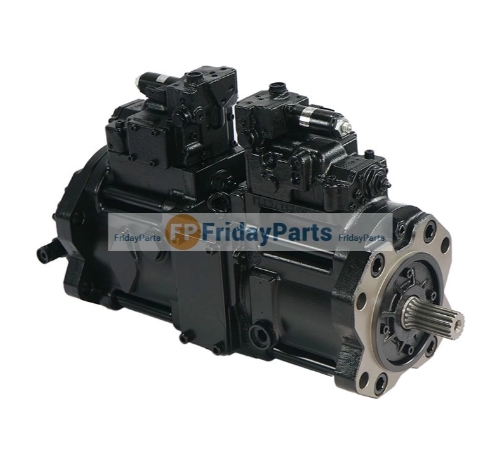

A hydraulic pump is responsible for converting mechanical energy into hydraulic energy, driving various actuators in hydraulic systems, such as cylinders and motors, by increasing fluid pressure. Similar to a water pump, it creates hydraulic energy through rotation, transmitting fluid pressure throughout the system.

Why adjust hydraulic pump pressure?

Proper pressure regulation is essential in hydraulic systems. Excessive pressure can cause seal leaks, pipe bursts, valve damage, while low pressure can impair system function and efficiency. Adjusting hydraulic pump pressure ensures system integrity, protecting components and optimizing performance.

Common methods for adjusting hydraulic pump output pressure include adjusting relief valves at the pump’s rear and pressure control valves at the front. Both can be tailored to application needs. However, adjusting pressure control valves requires extra caution to prevent damage from excessive pressure.

When inspecting, if you find the fluid level in the reservoir is below the pump’s operating level, it indicates the need for adjustment. System failures due to low fluid levels or excessive pressure, such as reduced pump efficiency or noise, can be avoided by regular checks of fluid levels and pressure.

Steps to adjust a hydraulic pump output pressure

If you encounter these issues, make sure to inspect the relief valve, pressure control valve, flow control valve, and pressure regulating valve to ensure they are set correctly. If the valves are improperly set, the problem can be resolved by adjusting them.

Before you begin, ensure that the engine of the farm machinery is turned off and the hydraulic system is in the released state to prevent accidental hydraulic pressure release and injury.

Adjusting the output pressure

Properly adjusting the output pressure of the hydraulic pump to the required level is crucial and varies depending on the equipment and model you have. This is especially important for mowers, as it affects cutting performance and effectiveness.

Identify the adjustment screw

Hydraulic pumps typically have an adjustment screw for adjusting the output pressure. This screw is usually located on the adjustment valve or the side of the pump.

Use a pressure gauge

Attach a pressure gauge to the appropriate port of the hydraulic system. It can measure the current output pressure of the hydraulic pump.

Adjust the screw

Using a wrench, loosen the locking nut and slowly rotate the adjustment screw. Clockwise rotation increases the output pressure, while counterclockwise rotation decreases it. Gradually adjust the screw in the desired direction according to your needs, and lock it into place. At the same time, you can monitor the pressure gauge readings.

*Before adjusting the output pressure of the hydraulic pump, be sure to read and follow the instructions for the hydraulic pump.

Test and adjust

After adjustment, restart the farm machinery and perform tests. If the desired output pressure is not achieved, adjustments to the relief valve or output valve may be necessary. Remove the cover and rotate the adjustment screw until the desired output pressure is reached.

Conclusion

Regular maintenance and adjusting the hydraulic pump’s output pressure is a cost-effective way to save you time and money. Not only does it help optimize performance and extend the lifespan of your equipment, but it also reduces wear and tear on the hydraulic system. By following the tips in this article, you can easily adjust the pressure and minimize system wear. For more guides, check out our blogs or contact us.

Leave A Comment