Most construction machinery is powered by internal combustion engines that run on diesel fuel. Diesel fuel provides the power for them and can last for a long time depending on the rate of consumption. As you know the fuel filter plays a crucial role in maintaining the performance of the equipment, but it doesn’t last forever. Over time, debris and dirt can accumulate in the fuel filter, reducing fuel efficiency and potentially causing generator malfunctions or damage.

To prevent debris from entering the generator’s fuel system, it is essential to regularly replace or clean the diesel fuel filter. If they are made of nylon or paper, you’d better replace it with a new one. If the filter is made of metal and is not excessively dirty, you can clean it and reuse it.

What is fuel filter cleaning?

Even if you remember to regularly maintain your diesel engine, you may overlook the quality of the fuel it contains. Thus, the fuel quality can deteriorate without you noticing until it’s too late.

Poor-quality fuel is primarily caused by contaminants entering the engine or fuel tank. These contaminants include:

- Water (the most common contaminant, which reduces the lubricating quality of the fuel and can cause injector sticking and engine damage)

- Rust (may caused by water, leading to corrosion)

- Soot

- Dirt

- Microbial growth (bacteria, mold, and yeast)

- Organic compounds produced by microbial activity

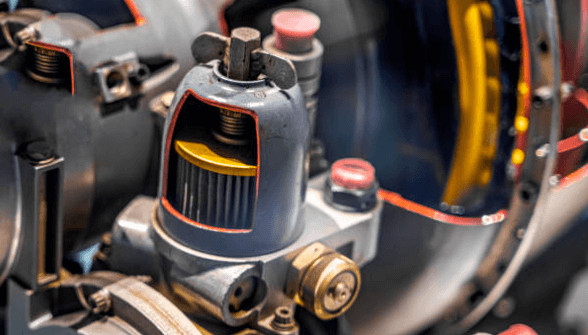

Purpose of a fuel filter

The main purpose is to remove and prevent impurities in the fuel, protecting the proper functioning of the fuel system. It captures tiny particles through its filter element. The filter housing has pleated filter elements to increase surface area and fuel flow.

Using a fuel filter effectively prevents impurities from entering the fuel system, protecting critical components, extending the life of the fuel system, and ensuring a reliable fuel supply. Regularly replacing the fuel filter is an important step in maintaining the health of the fuel system.

Why is fuel filter cleaning important?

The poor-quality fuel leads to negative effects on the engine, such as injector wear, fuel filter clogging, increased risk of incomplete combustion, and carbon buildup. In severe cases, it can lead to engine failure. Now take a look at the steps for the cleaning guide.

How to clean a diesel fuel filter?

Locate the diesel fuel filter

The first step is to know where it is located. Generally, diesel fuel filters are usually located in the engine compartment, but this can vary for different vehicles. Please refer to the vehicle’s user manual, which provides detailed instructions on the filter’s location, replacement process, and precautions.

Check the user manual

This step helps to understand specific guidelines and recommendations for cleaning the diesel fuel filter. Some equipment manufacturers may not recommend cleaning the filter and instead recommend replacing it with a new one.

Ensure Safety

Before cleaning the filter, ensure that you are operating in a safe environment, such as a well-ventilated area. Also, make sure to follow any relevant safety guidelines and use appropriate personal protective equipment, such as gloves and goggles.

Disassemble the filter

As per the instructions in the user manual, remove the filter from the vehicle. This may involve loosening bolts, fittings, or other connections.

Visual inspection

Visually inspect the filter to assess its condition. Observe if the filter element is heavily contaminated, clogged, or damaged. If the filter element is heavily contaminated or damaged, it is recommended to replace it with a new filter.

Clean the filter element

If you decide to attempt cleaning the filter element, use the right way and tools for cleaning. Note that different types of filter elements may require different cleaning methods. For example, some filter elements can be cleaned by gently tapping or using compressed air to blow off debris, while others may require soaking and cleaning with specific cleaning agents. Ensure that you use a dedicated cleaning agent suitable for diesel fuel filters and follow the instructions provided by the cleaning agent manufacturer.

Rinse and dry

After cleaning the filter element, rinse it with clean water to remove any residual cleaning agent and debris. Then, allow the filter element to air dry or use low-pressure air to dry it. Ensure it is completely dry to prevent water or moisture from entering the fuel system.

Reinstall the filter

Then, follow the instructions in the user manual to reinstall the filter into the vehicle. Ensure proper connection and tightening of all bolts, fittings, or other connections.

Test and inspect

After reinstalling the cleaned filter, start the vehicle and perform a test. Ensure that the fuel system is functioning properly and there are no leaks or abnormalities. Monitor the performance of the vehicle over the next few days to ensure that the cleaning process is successful and the fuel filter is operating effectively.

Although it is a cost-effective option to clean the fuel filter, some equipment manufacturers recommend replacing the filter rather than cleaning it. After all, if the filter is severely damaged or heavily contaminated, replacement is the best course of action. Regarding the filter, two options for you: expensive and perfect original equipment manufacturer (OEM) filters or cost-effective aftermarket diesel fuel filters with OEM quality assurance.

TLDR

No matter how brilliant a diesel fuel filter is, it won’t remain in perfect condition indefinitely. It can accumulate dirt and debris during operation, affecting its lifespan. To prolong its usability, you should inspect and clean it regularly. Hopefully, this guide can assist you. About the filter, choose OEM filters or aftermarket diesel fuel filters based on your budget. If you’re interested in aftermarket parts, welcome to explore them at fridayparts.com.

Leave A Comment